Introduction

When it comes to metal casting, two materials dominate the conversation: stainless steel and carbon steel. Both are strong, durable, and versatile, making them indispensable across industries such as automotive, construction, aerospace, petrochemicals, and heavy machinery. But despite their similar appearances and shared applications, stainless steel castings and carbon steel castings differ significantly in composition, performance characteristics, cost implications, and long-term reliability.

Understanding these differences is crucial not just for engineers and manufacturers but also for procurement teams and business owners who want to make informed decisions. Choosing the wrong material can lead to premature failures, corrosion issues, increased maintenance costs, or high upfront expenses that could have been avoided.

This blog provides a detailed comparison between stainless steel and carbon steel castings, exploring their chemical composition, mechanical properties, corrosion resistance, casting behavior, and typical applications. By the end, you will have a clear picture of which material suits your project best.

What Are Stainless Steel Castings?

Stainless steel castings are produced from steel alloys containing a minimum of 10.5% chromium, along with possible additions like nickel, molybdenum, or nitrogen. The presence of chromium forms a thin, self-healing oxide layer on the metal’s surface called the passive layer that gives stainless steel its exceptional corrosion resistance.

In the casting industry, stainless steel is preferred for applications where the components must withstand harsh environments, corrosive chemicals, high temperatures, or strict hygiene requirements.

Key characteristics of stainless steel castings include:

-

Outstanding corrosion resistance.

-

High strength-to-weight ratio.

-

Excellent heat and chemical resistance.

-

Long service life.

-

Modern, clean surface finish.

Stainless steel is widely used in marine equipment, food processing machinery, pumps, valves, and chemical plants.

What Are Carbon Steel Castings?

Carbon steel castings are made from iron-carbon alloys that contain up to 2.1% carbon. Unlike stainless steel, carbon steel does not contain significant amounts of chromium or other alloying elements. Instead, its performance relies on the carbon content, which greatly influences hardness, tensile strength, and wear resistance.

Carbon steel is one of the most widely used materials in the casting industry due to its affordability, machinability, and high mechanical strength.

Key characteristics of carbon steel castings include:

-

High strength and impact resistance.

-

Excellent toughness.

-

Cost-effectiveness.

-

Easy weldability and machinability.

-

Suitable for heavy-load and structural applications.

Carbon steel castings are commonly used in industrial machinery, automotive components, mining equipment, and construction.

Chemical Composition -The Fundamental Difference

The most important difference between stainless steel and carbon steel castings lies in their composition.

Stainless Steel Composition

-

Chromium: 10.5% or more.

-

Nickel: 0–20% (depending on grade).

-

Molybdenum: 0–3%.

-

Carbon: Low (often <0.08%).

The chromium content is essential for corrosion resistance, while nickel enhances strength and ductility.

Carbon Steel Composition

-

Carbon: 0.05% to 2.1%.

-

Manganese: Around 1%.

-

Silicon: Around 0.5%.

-

Chromium: Minimal or none.

The higher carbon content gives carbon steel its characteristic hardness and strength but reduces corrosion resistance.

Corrosion Resistance-The Biggest Advantage of Stainless Steel

If corrosion protection is a priority, stainless steel is the clear winner. The chromium oxide layer prevents rust even when the surface is damaged or scratched.

Stainless Steel

-

Excellent resistance to rust.

-

Withstands moisture, chemicals, acids, saltwater.

-

Ideal for marine, chemical, and food-grade applications.

Carbon Steel

-

Highly prone to rust.

-

Requires protective coatings or paints.

-

Not suitable for corrosive environments without treatment.

This makes stainless steel cost-effective in corrosive environments despite its higher initial price.

Strength and Hardness A Closer Look

Both materials offer high strength, but carbon steel often has the upper hand in load-bearing and impact-resistant applications.

Stainless Steel Strength

-

High tensile strength.

-

Good ductility.

-

Retains strength at high temperatures.

-

Suitable for pressure-containing components.

Carbon Steel Strength

-

Superior impact resistance.

-

Higher hardness with increasing carbon content.

-

Excellent fatigue resistance.

-

Suitable for heavy-duty industrial applications.

Carbon steel is generally the preferred choice where impact, load, and wear resistance are critical.

Heat Resistance -Which Performs Better?

Stainless Steel

Stainless steel has excellent resistance to heat. Grades like 304, 316, and 310 can withstand high operating temperatures without losing strength or deforming. This makes it ideal for furnace parts, exhaust systems, and heat exchangers.

Carbon Steel

Carbon steel has good strength at moderate temperatures but begins to lose structural integrity at high heat. It is not recommended for continuous high-temperature applications.

Casting Behavior – How Do They Perform in Foundries?

The casting process differs for both materials due to their melting points, fluidity, and shrinkage properties.

Stainless Steel Casting Behavior

-

Higher melting point.

-

Difficult to cast compared to carbon steel.

-

More prone to shrinkage and defects.

-

Requires precise temperature control.

-

Slower solidification.

This explains why stainless steel castings are usually more expensive and require experienced foundries.

Carbon Steel Casting Behavior

-

Easier to melt and pour.

-

Better fluidity.

-

Lower shrinkage.

-

Suitable for complex shapes.

-

Higher production efficiency.

Carbon steel is cheaper and easier to cast, making it ideal for mass production.

Machinability & Weldability

Stainless Steel

Stainless steel is harder to machine due to its toughness. It generates heat quickly, which can lead to tool wear. However, it welds well with the right techniques and filler materials.

Carbon Steel

Carbon steel offers:

-

Excellent machinability.

-

Easy welding.

-

Faster cutting and drilling.

-

Lower tooling costs.

Cost Comparison – Stainless Steel vs. Carbon Steel

Stainless Steel Cost Factors

-

Expensive alloying elements (Cr, Ni, Mo).

-

Higher casting difficulty.

-

Higher machining costs.

-

Long-term savings due to corrosion resistance.

Carbon Steel Cost Factors

-

Much lower material cost.

-

Faster casting production.

-

Lower machining costs.

-

Requires coatings for corrosion protection.

For cost-sensitive projects, carbon steel is preferred. For long-term durability in harsh conditions, stainless steel provides better value.

Where Are These Materials Used?

Stainless Steel Casting

-

Marine components.

-

Valve bodies and pump housings.

-

Food processing machinery.

-

Medical equipment.

-

Chemical and pharmaceutical plants.

-

Heat-resistant components.

-

Cleanroom and hygienic applications.

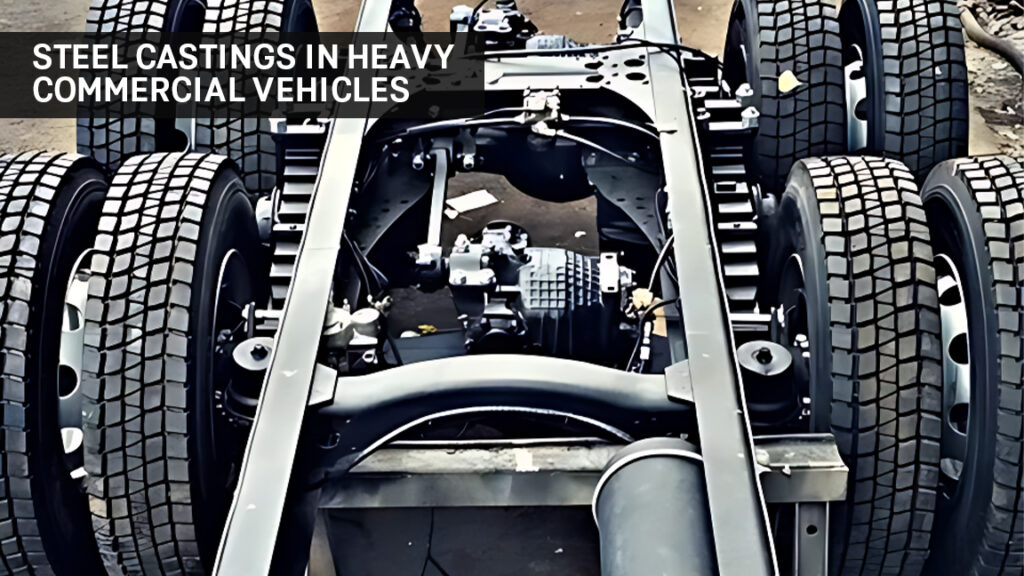

Carbon Steel Casting

-

Automotive components.

-

Construction machinery.

-

Mining and earth-moving equipment.

-

Agricultural machinery.

-

Heavy-duty industrial parts.

-

Gearboxes, couplings, and hubs.

Each material has a specific industry niche based on performance.

Conclusion

The choice between stainless steel and carbon steel castings depends mainly on the operating environment, mechanical requirements, and budget considerations. Stainless steel offers superior corrosion resistance, longevity, and heat performance, making it ideal for challenging environments. Carbon steel, on the other hand, provides exceptional strength, toughness, and cost-efficiency, making it a preferred choice for structural and heavy-duty applications.

Understanding these differences helps engineers, designers, and procurement teams make decisions that reduce maintenance costs, improve product lifespan, and ensure optimal performance.

If you’re looking for high-quality castings whether stainless steel or carbon steel partnering with a reliable and experienced casting manufacturer will ensure consistent performance, precision, and durability.

So, if you are interested to import best quality steel casting product from India, Get in touch with us.