Introduction

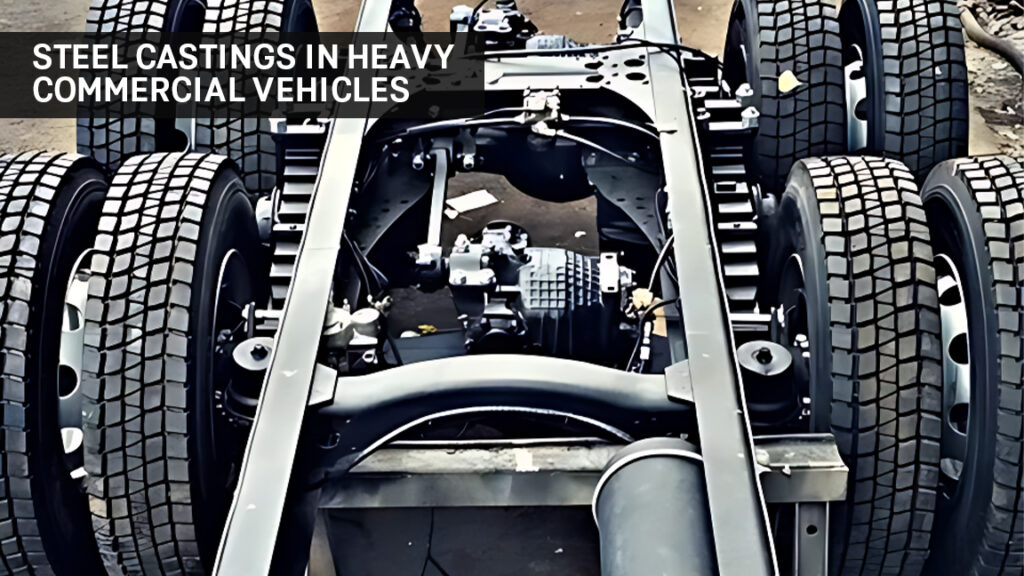

Heavy commercial vehicles (HCVs) are the backbone of modern logistics, infrastructure development, and industrial transportation. From long-haul trucks and tippers to buses, trailers, and construction machinery, these massive vehicles are designed to carry extreme loads, withstand intense operating conditions, and deliver consistent performance over extended lifespans. At the heart of their durability and reliability lies a critical engineering component steel castings.

Steel castings are integral to building the strong, high-performance parts that heavy commercial vehicles rely on. Their unique mechanical properties, strength, and versatility make them indispensable across major vehicle systems, including the chassis, suspension, braking mechanisms, housings, differential components, engine mounts, and much more.

This blog explores the essential role steel castings play in heavy commercial vehicles, the reasons behind their widespread usage, and how modern steel casting techniques contribute to the advancement of automotive manufacturing.

Understanding Steel Castings in the Automotive Sector

Steel casting is the process of pouring molten steel into accurately designed moulds to create complex shapes that cannot be produced easily through forging, machining, or fabrication. The resulting product delivers outstanding strength, durability, and performance, making it ideal for heavy-duty automotive applications.

In heavy commercial vehicles, components must endure high stress, heavy vibrations, thermal variations, and continuous mechanical strain. Steel castings excel under such conditions due to their robustness and structural superiority. Whether used in engine components or suspension systems, they contribute significantly to safety, reliability, and vehicle lifespan.

Why Steel Castings Are Essential for Heavy Commercial Vehicles

1. Exceptional Strength and Load-Bearing Capacity

Heavy commercial vehicles operate under extreme loads and harsh working conditions. Steel castings possess remarkable tensile strength, excellent fatigue resistance, and significant impact tolerance. These qualities allow critical vehicle structures to function safely under heavy stress, ensuring stability even when transporting maximum payloads.

Steel castings can endure:

-

High torsional forces.

-

Sudden impact during off-road movement.

-

Repetitive load cycles.

-

Continuous vibration.

This makes them ideal for components such as differential housings, axle assemblies, suspension brackets, engine supports, and steering knuckles.

2. Ability to Create Complex and Critical Shapes

Many heavy vehicle parts require intricate designs that must be lightweight yet strong enough to perform efficiently. Steel casting technology allows engineers to develop geometrically complex parts that are difficult or impossible to produce through traditional forging or machining.

Examples include:

-

Intricate brake components.

-

Precision transmission housings.

-

Advanced turbocharger mounts.

-

Custom-designed axle supports.

This ability to combine complexity with strength helps manufacturers fabricate parts that enhance both safety and performance.

3. Durability and Long Service Life

HCV parts must withstand years of rugged service often under the most punishing conditions. Steel castings provide the durability necessary to support these vehicles throughout their lifecycle. When exposed to corrosion, dirt, heat, and extreme weather, cast steel maintains its structural integrity better than many alternative materials.

This durability translates to:

-

Reduced maintenance needs.

-

Lower part replacement costs.

-

Longer vehicle lifespan.

-

More reliable performance in demanding environments.

For industries like mining, construction, logistics, and transportation, durability is not optional it is a necessity.

4. Cost Efficiency in Mass Production

While the initial design phase of casting requires careful engineering, the production process offers economical scalability. Once moulds are created, the same design can be reproduced consistently with minimal material waste.

This contributes to:

-

Uniform quality across all parts.

-

Lower per-unit production cost.

-

Efficient large-scale manufacturing.

For commercial vehicle manufacturers, this cost advantage allows production at competitive pricing without compromising part quality.

Major Applications of Steel Castings in Heavy Commercial Vehicles

Steel castings are used across multiple systems in HCVs. Here are some of their most critical applications:

1. Suspension Systems

The suspension system ensures vehicle stability, load distribution, and passenger/driver comfort. Steel castings are essential in manufacturing:

-

Suspension brackets.

-

Torque rods.

-

Spring seat brackets.

-

Control arms.

-

Stabilizer components.

As these parts frequently absorb shock and vibrations, steel’s high fatigue resistance ensures long-lasting performance.

2. Engine and Powertrain Components

HCV engines generate tremendous power, thermal stress, and vibrations. Steel castings are necessary for parts such as:

-

Turbocharger housings.

-

Flywheels.

-

Engine brackets.

-

Gearbox housings.

-

Crankshafts (in some applications).

The heat resistance and mechanical strength of steel ensure consistent performance even under heavy loads.

3. Brake and Safety Components

Safety is a top concern in heavy commercial vehicles, especially because braking systems experience immense heat and pressure. Steel castings are vital in fabricating:

-

Brake drums.

-

Caliper brackets.

-

ABS housings.

-

Brake anchoring parts.

A minor failure in these components can lead to catastrophic consequences, making the reliability of steel castings indispensable.

4. Chassis and Structural Elements

The chassis forms the backbone of every heavy commercial vehicle. Steel castings provide:

-

Supporting brackets.

-

Mounting joints.

-

Cross members.

-

Tow hooks.

-

Structural reinforcements.

These parts contribute to the rigidity and strength of the vehicle frame, ensuring safety and long-term stability.

5. Steering System Components

Steering systems require precision engineering to ensure safe maneuverability. Steel castings are used to create:

-

Steering knuckles.

-

Pitman arms.

-

Steering brackets.

-

Joint housings.

Their strength ensures stability during high-speed turns and off-road movements.

How Steel Castings Enhance Performance of Heavy Commercial Vehicles

1. Improved Load Capacity

Since many cast steel parts form the load-bearing structure of the vehicle, they directly influence payload capacity. Stronger components allow vehicles to carry heavier loads without compromising safety.

2. Enhanced Fuel Efficiency

While steel is heavier than some modern alternatives, its strength allows engineers to design thinner, lighter parts using precision casting. This reduces overall vehicle weight, leading to better fuel efficiency without sacrificing durability.

3. Increased Safety

Steel cast components contribute to safety by providing structurally dependable parts that withstand high stress. Brake components, steering knuckles, and suspension systems made from cast steel ensure stability and accident-free operation.

4. Resistance to Wear and Environmental Conditions

Heavy commercial vehicles often operate in dusty, corrosive, or high-moisture environments. Steel castings resist corrosion, heat damage, and mechanical wear better than many alloys, resulting in better longevity and performance.

The Future of Steel Castings in Heavy Commercial Vehicles

As the heavy vehicle industry grows, the demand for stronger, lighter, and more efficient vehicle components continues to rise. Steel casting manufacturers are focusing on:

-

Lightweight steel alloys.

-

High-strength low-alloy (HSLA) castings.

-

Optimized casting geometries.

-

Improved machining techniques.

-

Hybrid material integration.

With modern engineering, steel castings remain at the forefront of vehicle strength and safety, even as the industry moves towards electric heavy commercial vehicles.

Conclusion

Steel castings are the unseen yet essential heroes of heavy commercial vehicles. From the chassis to the engine, the suspension system to safety-critical brake parts, steel castings enable these massive vehicles to perform safely, efficiently, and reliably. Their unmatched strength, versatility, cost-effectiveness, and durability make them an indispensable part of automotive engineering.

As technology continues to advance, steel castings will play an even more crucial role in shaping the future of heavy commercial transportation ensuring better performance, higher load capacity, improved safety, and longer service life.

So, if you are interested to import best quality steel casting product from India, Get in touch with us.